RTWC, RTWK and Rł grates with a heavy base are designed for coal dust combustion in layers using water-tube boilers and steam boilers with a maximum capacity ranging from 3 MW to 60 MW.

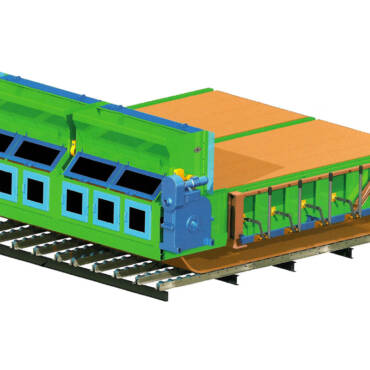

Depending on the capacity of the boiler, high grates are available as single-base grates or dual-base grates (a dual grate has two bases next to each other).

Single-base grates are intended for 3-20 MW boilers.

Dual-base grates are intended for 25-60 MW boilers.

Our designers and structural engineers take advantage of the latest advances in technology to deliver low, medium and high boiler grates and other equipment that help increase combustion efficiency and the capacity of the boiler. The excess air coefficient and the oxygen content of flue gas can be reduced as a result.

Technical specifications of high boiler grates:

- maximum heat load: 1280 kW/m2,

maximum calorific value of fuel: 19÷25 MJ/kg,

maximum fuel layer thickness: 0.15 m.

These grates are powered by BNr2000 or BNr1000 drives designed to be used with a frequency converter.

What are the parts of a high boiler grate?

High boiler grates designated as RTWC, RTWK and Rł are supplied with a heavy base.

The air-boxes of the grates are divided into airtight zones. The number of such zones depends on the boiler type and the effective length of the grate. The optimum number of such zones should be based on the number of “dead” spaces between the zones in relation to the total usable area of the grate. A zone is a space surrounding the air hopper, between the (a) partition sheets running to the side walls of the grate and (b) th bottom and the grate base. The air boxes are designed to supply fresh air separately to each such zone and to ensure that the spaces between the zones are completely airtight. Air is supplied and controlled via a blower air supply system installed outside the grate. This allows the operator to control the amount of air that is supplied to each zone of the grate.

The combustion efficiency on the grate is 97.5% with the nominal boiler output range of 50-100%.

The heavy grate base (which consists of a t-203 chain, left-side holders, right-side holders, a JW-type holder, an OW-type holder, rollers, spacing pipes, pins and 395 or 245 grate bars) is available as a standard option or with higher resistance to heat (for example, the chain is made of chromium-manganese steel, grate bars with a chromium content of up to 2.5%).

If you are interested in our products, contact us. Our consultants will tell you about the available options and provide you with detailed technical specifications of our products. All this is to ensure that your boiler grate meets the requirements of your industrial processes.