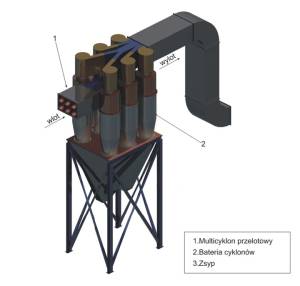

A two-stage dust collector consists of an axial multicyclone dust collector and a cyclone separator set. It serves to increase the efficiency of a dedusting system and to maintain its performance at the highest possible level. With a compact-size two-stage dust collector installed in your dedusting system, the outlet dust concentration level will be lower than 300 mg/m3u at 6% oxygen content in the waste gas.

What are the features of cyclone separator sets and multicyclone dust collectors?

Cyclone separator sets are made of 5 mm-thick sheets of regular structural steel. The inlet head may come with an insert made of wear-resistant steel, or Hardox, to increase the lifetime of the head. Cyclone separator sets can also be used as initial dust removers for, for example, filter bags.

The key characteristics of our cyclone separator sets are:

dust content in the inlet gas: 6 g/m3,

dust content in the outlet gas: 200-300 mg/m3 at 6% oxygen content in the waste gas,

maximum working temperature: +300°C.

An axial multicyclone separator is used as a first stage dust collector in a dust removal (or dedusting) system. It removes the most erosive fractions, which increases the lifetime of cyclone dust collectors or filters.

Technical specifications of ZUK’s multicyclone dust collectors:

- axial multicyclone separator diameter: Ø 250 or Ø 315 (item 1)

- recommended flow rates (item 2):

for an axial multicyclone separator diameter of Ø 250: 0.6 m3/sec,

for an axial multicyclone separator diameter of Ø 315: 1 m3/sec,

- the capacity of a single axial multicyclone separator depends on the number of such separators in a system and on the diameter.

If you are interested in our products, contact us. Our consultants will tell you about our business terms and provide you with detailed technical specifications of our products.