ZUK Stąporków holds the following qualifications and certifications

Certification of our Integrated Management System according to the PN-EN ISO 9001:2015, PN-EN ISO 14001:2015 and PN-ISO 45001:2018 standards

- Design, construction and execution of: machinery, equipment and power installations, steel structures, steel construction elements and construction formwork,

- Implementation of turnkey industrial investment projects regarding the design and production of systems.

Certificate of Factory Production Control Conformity, No. 2527-CPR-1A.033.03

Welder’s Qualification Certificate

- Execution of steel structures and aluminium structures according to the requirements of the EN 1090-2:2018 standard

- Mechanical cutting

Thermal cutting

Cold forming

Hole drilling

Mechanical joining

Surface preparation

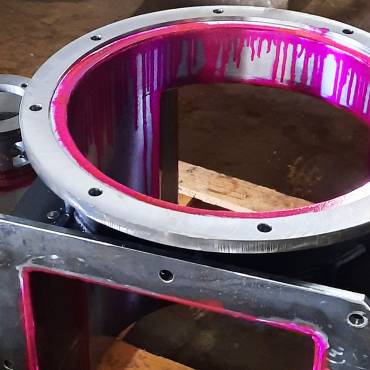

Protective treatment of surfaces

Certificate of compliance with the PN-EN ISO 9001:2015 standard (Quality Management System)

Certificate of compliance with the PN-EN ISO 14001:2015 standard (Environmental Management System)

EC and EU declarations of conformity within the meaning of the Machinery Directive (2006/42/EC) for products manufactured by ZUK Stąporków S.A.

NON-DESTRUCTIVE TESTING OF WELDS

ZUK Stąporków S. A. has qualified NDT personnel with competencies that meet the requirements of PN-EN ISO 9712:

visual testing (VT2) in the industrial, product and PED sectors (related to pressure equipment connections),

penetrant testing (PT2) in the industrial, product and PED sectors (related to pressure equipment connections),

magnetic particle testing (MT2) in the industrial, product and PED sectors (related to pressure equipment connections).

WELDING

We are qualified and licensed to fabricate steel structures covering the following classes:

- EXC1

- EXC2

- EXC3

according to the PN-EN ISO 1090 standard.

The company has qualified welding technologies (WPQR) according to EN ISO 15614 and EN 15613 for elements made of steel types S235JR÷ S690QL, X5CrNi18-10 (1.4301) ÷ X2CrNiMo17-12-2 (1.4404) and Alloy 59 for methods: 111, 135, 136 and 141.

Employees performing welded joints are tested in accordance with the requirements of PN-EN ISO 9606-1 “Qualification test of welders – Fusion welding – Part 1: Steels” for the following welding methods:

- 111: Manual metal arc welding with a coated electrode

- 135: MAG welding with a solid wire electrode

- : MAG welding with a solid wire electrode

- TIG welding with wire/solid bar

for material groups:

1.1 , 1.2 , 1.3 , 1.4 , 2.1 , 2.2 , 3.2 (for S690QL) , 7.1 , 8.1 , 8.2 , 43 , 1.2 + 8.1

SERVICES

Qualification certificates for G1 and G2 covering operation and supervision.

Our personnel are licensed to operate the necessary equipment:

- overhead cranes,

- movable platforms (manlifts), and

- forklift trucks.

For projects based in Scandinavia, our personnel

- hold the required HMS/HSE cards,

- are licensed to perform hot works, and

- have completed a fall protection course.