We have been designing and producing scraper conveyors (PPZ type) for years. These conveyors are widely used by power companies. They are made according to the highest quality standards, offering excellent durability. Each project is special to us and will be carried out according to your individual requirements so that your conveyor offers you the best capacity and efficiency under different working conditions. Professional warranty and post-warranty servicing is available to our customers. We are also prepared to design and produce dual-trough (OZGW type) and single-trough (OZDW type) conveyors for heavy industry applications.

What is the intended use of PPZ scraper conveyors?

These slag removers are used primarily with fire-tube boilers.

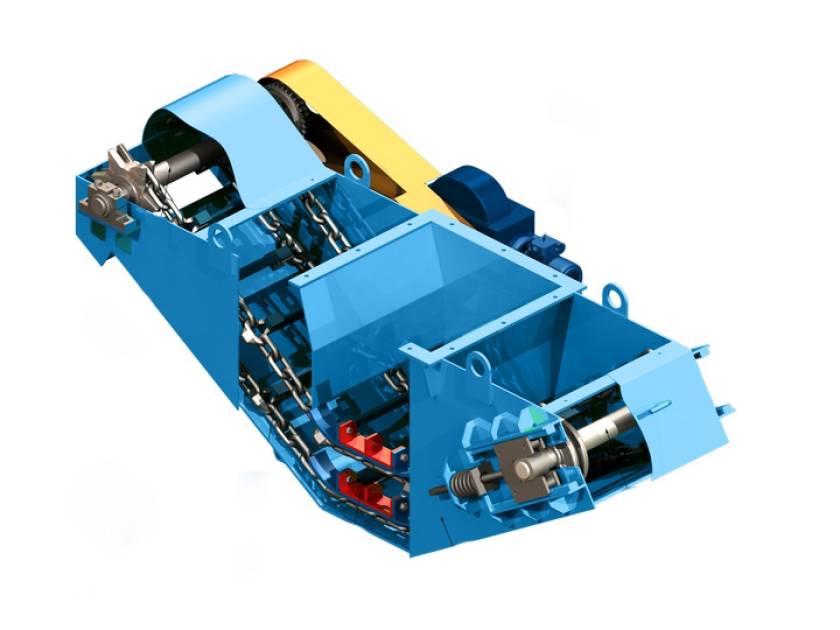

What are the parts of a PPZ scraper conveyor? They are:

a slag removal trough,

a front shaft and a rear shaft,

a scraping belt,

a motor drive, and

chain guides.

The maximum capacity of the conveyor is 0.8 MT per hour, and the motor power rating is 0.55 kW. The slides are replaceable parts. The drive mechanism consists of an electric geared motor and a chain gear. A pin fuse inside the wheel chain of the drive shaft is used as overload protection for the drive mechanism.

We will be happy to design a conveyor that meets your requirements in terms of capacity and power, as well as the size of the conveyor system or its individual parts, such as the drive shafts.