Bag filters are designed to remove dry and non-adhesive dust that does not mix to produce explosive mixtures – from flue gas, air and other gaseous substances. All our solutions offer high efficiency, low operation costs and excellent performance.

What are bag filters used?

A bag filter with an ATEX-certified protection system can be used to remove dust from explosive air and dust mixtures.

Vertical bag filters are used in industries such as

power engineering,

founding,

cement production,

lime production,

metallurgy,

heat generation, and

glass production.

They are also used to remove dust from the flue gas produced by power boilers. If you are interested in our products, contact us. We will tell you all about how you can use the solutions we can offer.

How do bag filters work?

Bag filters are replaced from the side of the clean air compartment.

Bag filters are replaced from the side of the clean air compartment.

in a cycle: compressed air is injected at a set interval,

- automatically: compressed air is injected when the pressure difference value exceeds the value set in the filter controller.

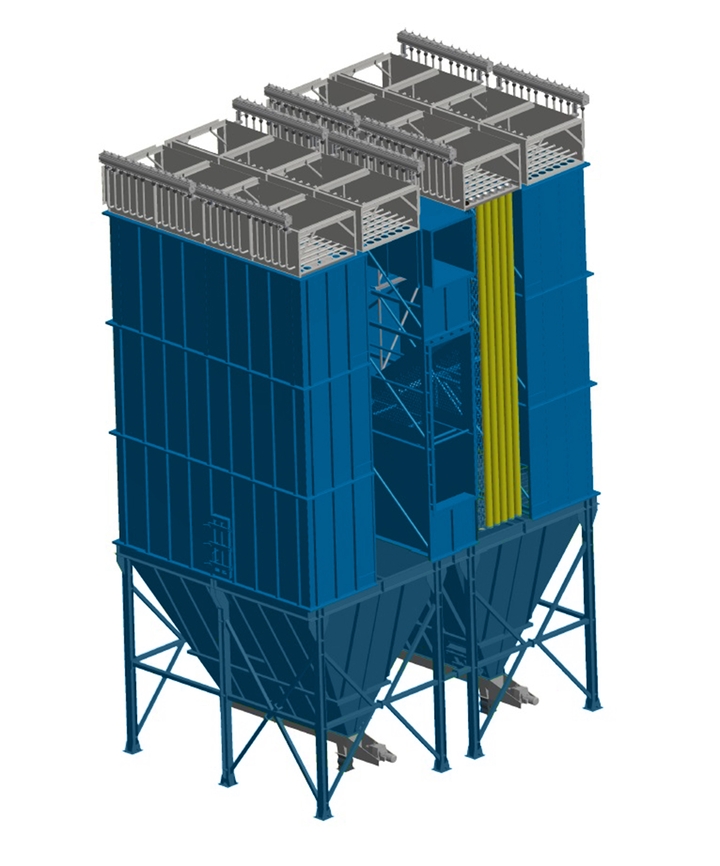

Each vertical bag filter consists of:

a support structure,

a chute,

a filtration compartment with a sediment duct,

a clean air compartment,

a roof structure,

a compressed air regeneration system,

bags and baskets,

maintenance platforms, barriers and ladders,

a dust removal system (a screw conveyor with a rotary fan feeder),

a controller cabinet.

All our bag filters are made according to designs and other documentation prepared by our team of experienced structural engineers and designers. Dedusting equipment can also be made according to customer-supplied documentation.