ZUK designs step grates for steam and water boilers with an output of up to 30 MW. Our customers are provided with technical advice and support. We will be pleased to answer your questions. We will design a step grate specifically for your project, according to your requirements and conditions at your site.

What is the intended use of a step boiler grate?

A step boiler grate will ensure that your boiler burns virtually any solid fuel efficiently. A step grate is easy to use, as the slag removal process is automated, as is the transport of biomass. This is ensured by movable, hydraulically operated grate bars, push rods and trolleys.

A step boiler grate can be used to burn the following biomass:

wood chips,

ground straw,

energy crops,

sawdust,

pellets,

heads of maize,

plant-based waste.

Our step grates can also be used for efficient combustion of hard coal with a low calorific value and alternative refuse-derived fuel (RDF).

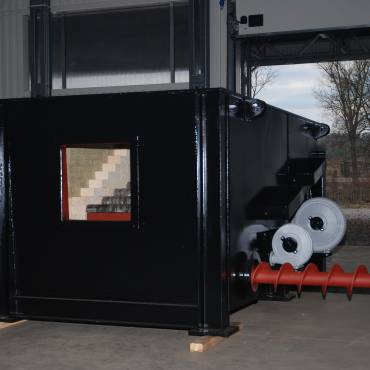

What are the parts of a step boiler grate?

A step boiler grate has a rigid framework. It can be used to support an exchanger or a ceramic pre-furnace. The air box is divided into separate zones, each supplied with fresh air produced by separate adjustable-capacity fans. The grate base is an arrangement of grate bars with a high content of chromium. The bars are arranged in alternate fixed and movable rows. Slag can be removed by a screw conveyor or a belt conveyor, depending on the grate design.