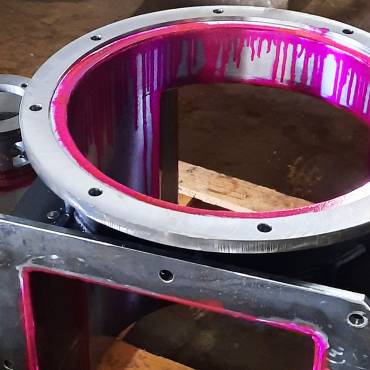

ZUK Stąporków S.A. offers a wide range of professional welding services. We use modern technology-based solutions to carry out projects according to the highest quality standards. Our personnel have the required qualifications and licences. This allows us to deliver what our customers expect when they turn to us as an expert in welding. Each project is special to us and each is carried out with the utmost care and diligence.

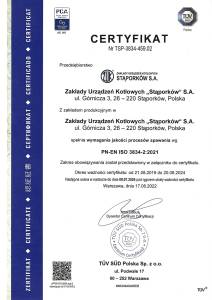

Qualifications and certifications (licences) in welding

We have been working for years to supply our customers with quality welding services. We make every effort to do all our technical work in compliance with the applicable standards and according to the customer’s requirements.

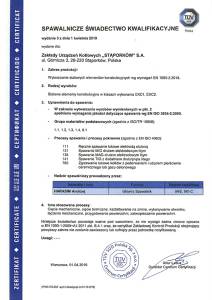

We have an in-house team of qualified welding supervisors as required by the PN-EN ISO 14731 standard.

Our specialists include international welding engineers (IWE’s) and

international welding inspectors (IWI’s).

We also have personnel qualified to perform non-destructive tests of welded joints using surface methods. The personnel are certified according to the PN-EN ISO 9712 standard.

We also have certified inspectors for anti-corrosion protection, namely a Frosio Inspector, level 3.

We are qualified and licensed to fabricate steel structures covering the following classes:

- EXC1

- EXC2

- EXC3

according to the PN-EN ISO 1090 standard.

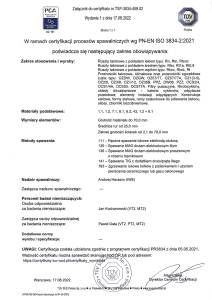

The company has qualified welding technologies (WPQR) according to EN ISO 15614 and PN EN 15613 for elements made of steel types S235JR÷ S690QL, X5CrNi18-10 (1.4301) ÷ X2CrNiMo17-12-2 (1.4404) and Alloy 59 for methods: 111, 135, 136 and 141.

Employees performing welded joints are tested in accordance with the requirements of PN-EN ISO 9606-1 “Qualification test of welders – Fusion welding – Part 1: Steels for the following welding methods:

111: Manual metal arc welding with a coated electrode

135: MAG welding with a solid wire electrode

136: MAG welding with a solid wire electrode

141: TIG welding with wire/solid bar

for material groups:

1.1 , 1.2 , 1.3 , 1.4 , 2.1 , 2.2 , 3.2 (do S690QL) , 7.1 , 8.1 , 8.2 , 43 , 1.2 + 8.1

What welding technologies can we offer?

We use various welding methods or technologies. The one for your project will depend on the structural requirements of your project and your individual needs. You can benefit from our steel welding services if your project involves the fabrication of non-pressurised tanks or other steel structures for use in the chemical, energy, mining and related sectors. If you are interested in our welding services, contact us. We will discuss our terms of business and tell you more about what our welders can do for you.

The quality of our welding work is supervised by qualified welding supervisors as required by the PN-EN ISO 14731 standard.

Our specialists include and international welding inspectors (IWI’s) and international welding inspectors (IWI’s).

We also have personnel qualified to perform non-destructive tests of welded joints using surface methods. The personnel are certified according to the PN-EN ISO 9712 standard.

We have certified inspectors for anti-corrosion protection, namely a Frosio Inspector, level 3.

For steel welding projects, we use machines such as

a Lorch welding unit designed to collaborate with a COBOT Universal UR10 robot.

modern welding machines: MAG (135), TIG (141) made by FRONIUS, EWM AG and LINCOLN ELECTRIC

an MSR-20 MOST self-adjustable welding rotator with a carrying capacity of up to 20 MT

an MCP-1 MOST conventional welding positioner with a carrying capacity of up to 1 MT

Non-destructive testing of welds (NDT)

ZUK Stąporków S. A. has qualified NDT personnel with competencies that meet the requirements of PN-EN ISO 9712:

The methods we use in such testing include

visual testing (VT) level 2,

penetrant testing (PT) level 2, and

magnetic particle testing (MT) level 2.

In volumetric non-destructive testing of welds, the methods we use include UT and RT. For such tests, we rely on the support of reputable and experienced laboratories, such as WELD-TEST Sp. z o.o and SOLDAR.

Feel free to learn more about our past projects.